Our Flow & Anti-Wear solutions, including the newly launched K-Floshield Polished High Chrome Liner, uphold the efficiency, integrity, and performance of processing bins, buckets, chutes, crushers, pugmills, and other bulk materials handling equipment.

Products: Flow & Anti-Wear Products

No additional content available for this category.

Frequently Asked Questions

Flow & Anti-Wear products are designed to enhance the performance and durability of bulk handling equipment. These solutions, such as the K-Floshield Polished High Chrome Liner, reduce wear and tear, ensuring smooth material flow and maintaining the structural integrity of processing bins, buckets, chutes, crushers, and pugmills.

The K-Floshield Polished High Chrome Liner is an enhanced material flow product that provides exceptional resistance to abrasion and wear in high-impact processing environments. It helps protect equipment from damage, extending its lifespan and improving operational efficiency.

Materials flow solutions help optimise the movement of bulk materials within processing systems. By ensuring a consistent and efficient flow, these solutions minimise blockages, reduce downtime, and enhance productivity.

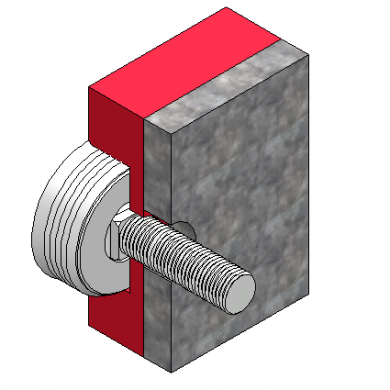

Anti-wear linings are specially designed materials that protect the surfaces of equipment from excessive wear and damage caused by abrasion and impact. They help prolong the lifespan of machinery and ensure more efficient operations, reducing the need for frequent repairs.

Magnetic wear, repair, and seal products are used to prevent hazardous liquid and bulk solid leakages. They offer a quick, simple and effective way to repair worn-out steel equipment, allowing the user to replace as required to keep production going until a scheduled permanent repair date.

If you operate bulk materials handling equipment that experiences high levels of abrasion and impact, it’s essential to use Flow & Anti-Wear products to safeguard your machinery, maintain smooth operations, and prevent costly downtime.