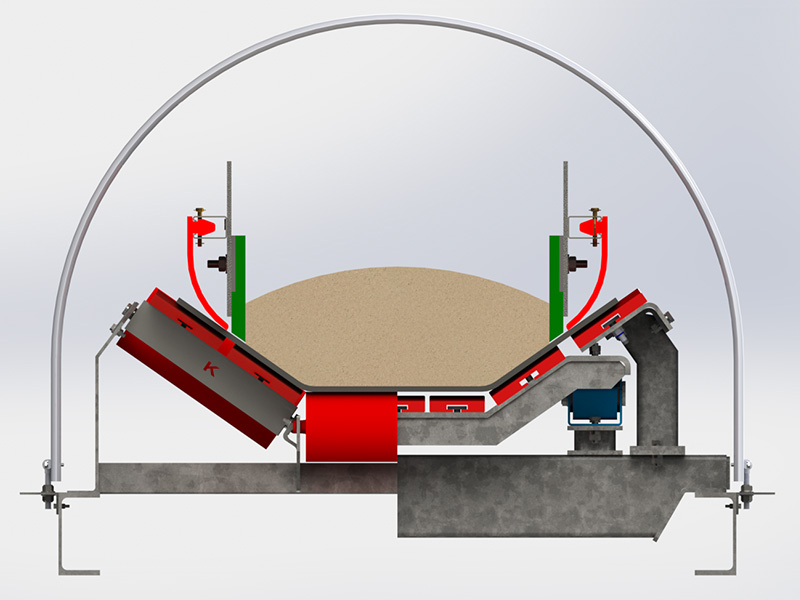

The effective suppression of dust particles around high pressure and poorly designed conveyor transfer points can be achieved by installing The Essential SNAP Seal – Dust Containment Combination.

A combined conveyor skirting & sealing, conveyor belt support and conveyor belt cover system is offered by Kinder Australia. “The Essential SNAP Seal” combination transforms high risk dust and material spillage transfer points into productive, efficient, safe and clean workspaces.

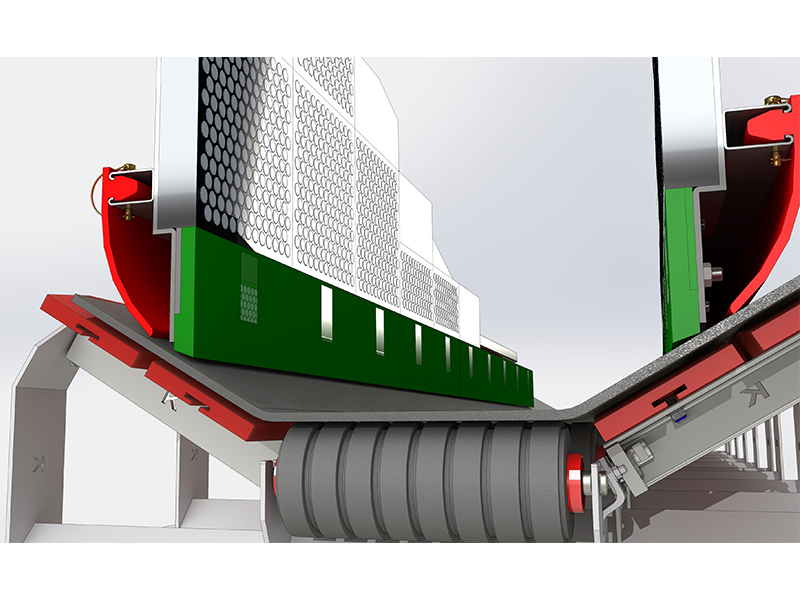

K-Sure® Belt Support System solves belt sag problems, where there are too few idlers installed at the loading point, a low friction support system under the belt, like K-Sure® will correct this. Providing a consistent and stable support for the troughed belt profile, eliminating any moving parts and their associated ongoing maintenance.

K-Shield Dynamax® Impact Belt Support System improves material containment at the conveyor’s transfer point in very high impact applications. The centre of the K-Shield Dynamax® Impact Bed is suspended on anti-vibration mounts which significantly reduces the risk of belt damage.

K-Snap-Loc® Dust Seal is an engineered option that is suitable for use in a wide variety of applications. It made from a high-performance polyurethane which can withstand even the most highly abrasive applications. (High temperature formulas available.)

The K-Containment® Seal enhances the success of the outer seal by reducing the high internal pressure experienced inside the chute and protects the vulnerable chute edges from damage.

Finally, “The Essential SNAP Seal” incorporates K-AllShelter® Conveyor Belt Covers – a protective barrier, aiding airborne dust reduction, protection from extreme environmental elements, helping to control moisture levels of conveyed materials, further controlling dust emissions.