K-Snap-Loc® Dust Seal System is a practical and cost-effective solution to dust control for all conveyor belt speed applications.

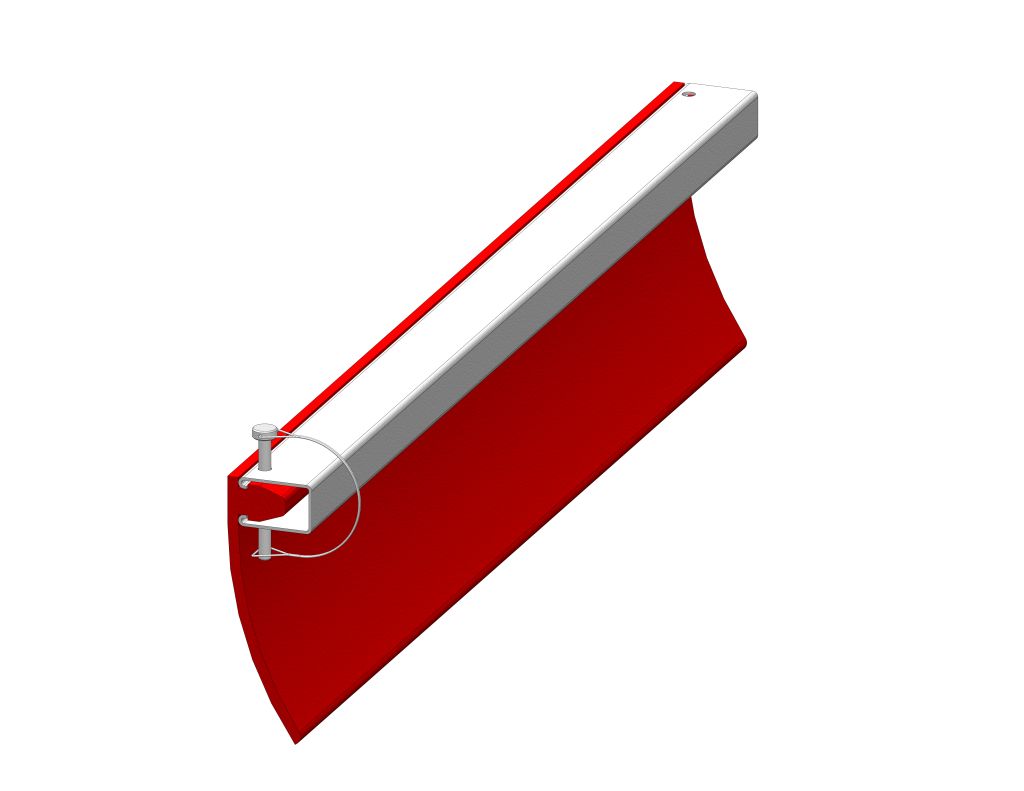

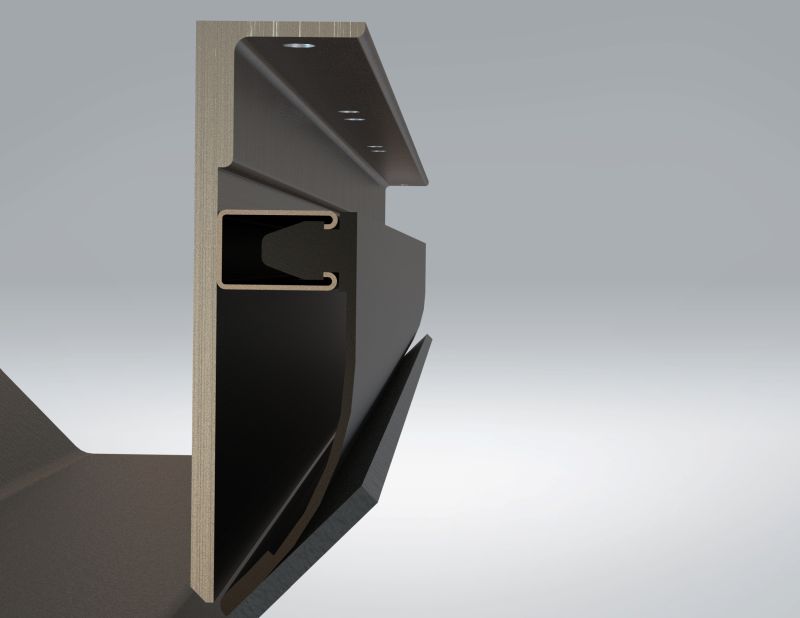

Its unique design installs into most conveyor systems. The Uni-Strut mounting can be welded to your existing system. The seal then snaps into place.

K-Snap-Loc® Dust Seal System is made from high performance engineered polyurethane which can withstand high abrasive and high temperature applications. There is a variety of formulas to suit high speed and hot applications.

The polyurethane’s inherent “memory-set” is used to apply downward pressure onto the belt’s surface to create a fine tight seal, so there is no need for manual adjustment.

Because of the low coefficient of friction there is a power saving by producing 60% less drag on the conveyor belt than traditional skirting rubber.

Key Features:

- Suitable for all belt widths and trough angles.

- Field tested with 8 to 10 times the wear life better than rubber.

- 60% less coefficient of friction than rubber.

- More energy efficient than rubber.

- High temperature formulas also available, contact Kinder.

- Available in fire retardant, fire resistant and anti-static formulas (consult our sales team for details).