K-Polymer® Enduro Conveyor Rollers

Engineered for optimum reliability and performance, Kinder’s K-Polymer® Enduro Conveyor Rollers offer a cutting-edge solution for materials handling operations across all industries.

These rollers represent a significant advancement in conveyor technology, addressing common challenges such as roller seizure, maintenance demands, and workplace safety risks.

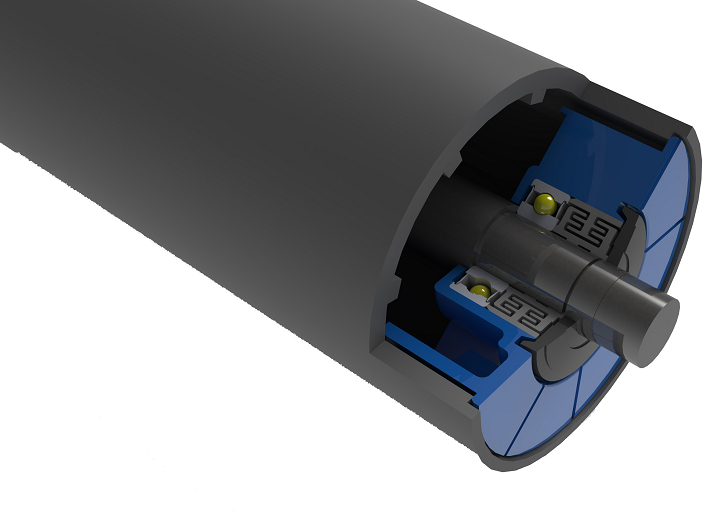

By incorporating a static end disc engineered design, these rollers eliminate many of the operational issues faced with traditional rollers. This innovation ensures smoother, more reliable performance, reduces maintenance downtime, and enhances the overall productivity of your materials handling operations.

K-Polymer® Enduro Conveyor Roller’s lightweight and corrosion-resistant construction makes them an ideal choice for industries prioritising efficiency, safety, and long-term cost savings.

Key Features:

- HDPE shell is lightweight yet durable.

- Static end disc reduces roller seizure risk.

- Contact V-Ring Seal blocks contaminants, extending roller life.

- Corrosion resistance properties ensure durability in harsh conditions.

- Minimises carry back and promotes cleaner operations.

- Weigh quality roller option also available upon request.

Key Benefits:

- Belt Friendly – Compared to traditional steel rollers.

- Safer Manual Handling – The lightweight design makes K-Polymer® Enduro Rollers easier to handle and install, reducing the risk of workplace injuries.

- Quieter Operation – Up to 7dB quieter compared to steel rollers. K-Polymer® Enduro Rollers generate less noise, creating a more comfortable working environment.

- Increased Reliability – Minimises downtime for maximised productivity.

- Lower Maintenance Costs – Durable construction reduces maintenance frequency and expenses.

Why Choose Kinder K-Polymer® Enduro Rollers

Unmatched Reliability

Static end disc design reduces the risk of seized bearings, minimising downtime and boosting productivity.

Enhanced Durability

High-density polyethylene (HDPE) shell offers exceptional strength and wear resistance while being significantly lighter than steel rollers. Corrosion-resistant materials ensure longevity, even in challenging environments.

Superior Protection

The Contact V-ring seals effectively block water and dust, safeguarding bearings for extended operational life.

Reduced Carryback

Smooth HDPE surface minimises material build-up, ensuring cleaner operation and less maintenance.

Choose Kinder K-Polymer® Enduro Conveyor Rollers to transform your materials handling system with unmatched durability, efficiency, and safety.

Available in a variety of sizes to suit your specific needs.

K-Polymer® Conveyor Rollers – Lightweight & Corrosion Resistant

The K-Polymer® Conveyor Roller is the new generation heavy-duty light-weight, alternative to a steel shell roller. It offers the best solution to roller failure caused by corrosion in humid and wet conditions. Although the roller is light-weight (approximately 50% that of steel) it is engineered using modern polymer and fibre (HDPE) materials to substantially out last steel. Comparative wear test proof is available on request.

The light-weight design means that risk of back injury is significantly reduced as manual handling is made easier, especially when carrying up steep inclines.

K-Polymer® Conveyor Rollers are in most cases self-cleaning by not allowing carryback to stick to the non-porous shell, causing mistracking, potential spillage or belt wear.

Rollers are interchangeable with existing steel rollers by having the same diameters, bearing and shaft sizes.

K-Polymer® Conveyor Rollers are installed in almost every type of belt conveying application.

They are fast becoming the preferred option over conventional steel rollers. Many users report the significant noise reduction compared to steel rollers and tests document their quiet operation.

Our standard stock range covers conventional interchangeable shaft Australian configurations, but all made-to-order dimensions can be accommodated. All components are recyclable.

Key Benefits:

- 50% less weight than steel.

- Belt friendly.

- Quiet.

- Corrosion, Wear, and UV Resistance.

Belt Range: 400 – 2000mm, Trough and Return.

Roller Diameters: 89mm, 102mm, 108mm, 114mm, 127mm, 133mm, 140mm, 152mm, 157mm. Other sizes available upon request.

Bearing Type: C&U Brand, LLB and C&U 2RS. Other brands available upon request.

Test Results: Rim Drag, TIR, Waterproof and Dust Proof, Dynamic Unbalanced Measurements available upon request.