Is clogged chute material slowing down your quarry?

If you’re experiencing bridging, arching, ratholing or clinging, chances are you’re also facing further productivity challenges:

- Blockages and downtime

- Increased wear and tear

- Spillage and product loss

- Damage to the chute

With nearly 40 years under out belt, Kinder’s field application specialists and engineers have seen these problems arise time and time again due to poorly optimised chutes and bin designs.

Stop chute issues before they start with Kinder’s engineered range of Material Flow Solutions.

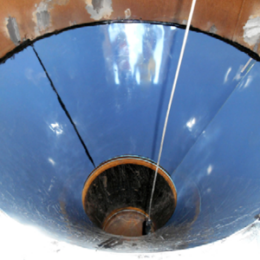

K-Slip Rubber Backed UHMWPE Wear Liner

- Very low co-efficient of friction

- Flexible and thin

- Suits complex shapes

“It improved flow effectively and it was also straightforward to apply” – Lead Engineer, Shale Operation [Read Case Study]

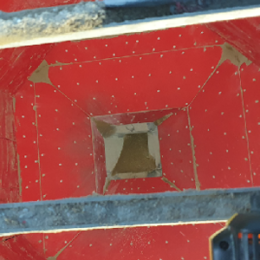

K-Slide UHMWPE Low Friction Liner

- Low co-efficient of friction

- Abrasion and corrosion resistance

- Range of grades / thickness / sheet sizes

“Productivity is at an all-time high with a minimal amount of product lost” – Manufactured Sand Plant [Read Case Study]

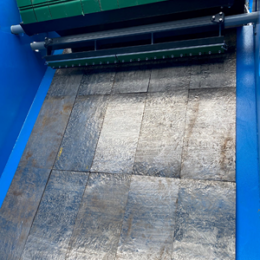

K-Floshield® High Polished Chrome Liner

- Extreme wear protection

- 5-6 times more wear resistant than steel

- Low co-efficient of friction

“Any wear was almost negligible and the initial weld line was still present in the wear liner” – Recycled Building Materials Facility [Read Case Study]