Kinder Australia offers a comprehensive conveyor belt supplies, single source, one-stop-shop total replacement conveyor roller and frames service. It covers practically any type of special conveyor roller or frame to suit existing installations or those which have been inherited or are pre-existing. Our national team of sales engineers are able to provide expert product knowledge combined with prior practical on-site application specific experience.

As there are no international standard measurements used across the variety of conveyor rollers and frames available, the choice of poor fitting shafts, slot dimensions and bearing series can eventually lead to premature failure of the roller or conveyor belt mistracking. All Kinder Australia conveyor rollers have international standard DIN coding (German Institute for Standardisation). Incorrect roller and frame dimension measurements will create suboptimal

conveyor performance and long-term structural damage to the belt itself, belt mistracking and material spillage due to ineffective initial roller fitting. When you need replacement conveyor rollers and frames, utilising our expertise, we are able to ensure for you that the most suitable interchangeable conveyor component is supplied.

Our commitment to ISO9001 Quality Assurance is achieved at both factory and warehouse stages. Our factory records an ITR (Inspection Test Report) on all manufactured conveyor rollers. When entering our warehouse, all items are then given an inventory part number and a stock order number. This creates a 2 stage quality assurance process and ensures that all items when supplied can be traceable to their manufactured source.

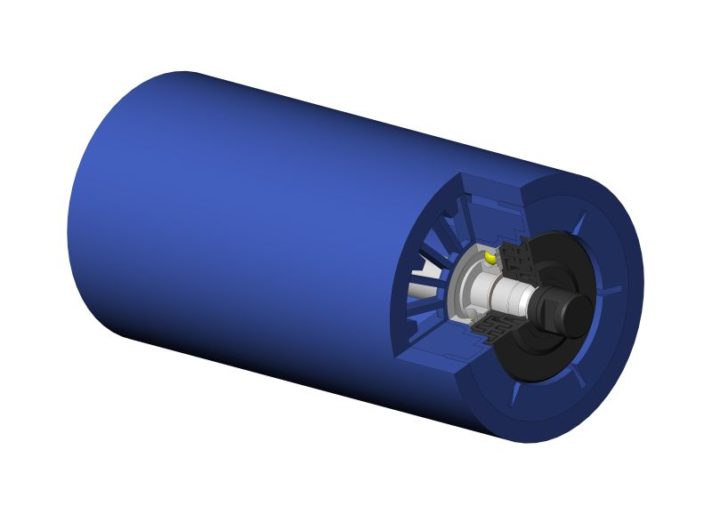

Replacement Roller Specifications:

It’s important to maintain the original correct belt line. Therefore brackets and roller dimensions should match the original setup. Equivalent rollers should maintain:

- External dimensions

- Shell thickness

- Internal shaft dimensions

- Bearing Series

- Seal Type

At Kinder Australia, our passionate motivation is to ensure your site operates in the safest environment possible. We achieve short supply lead-times for all of your conveyor supply requirements, resulting in improved productivity as efficiently and cost effectively as possible.