A fundamental component of the conveyor system are the idler frames. Considered the backbone of the conveyor system, if not well profiled and positioned correctly, the belt is at increased risk of misalignment. Misalignment can lead to uneven wear and damage to the conveyor belt itself, or disastrous material spillage.

The expanding selection of conveyor idler frames at Kinder Australia covers a wide range of applications depending on what the conveyor requires to operate efficiently.

Kinder Conveyor Idler Frames Range:

- Adjustable Conveyor Trough Frames (Inline & Offset)

- K-Vee Return Idler Frame

- K-HD Retractable Impact Frame

- K-Retractable Idler/Impact Frames

- K-Commander® Tracking Frames

- K-Ergo Swift Return Idler Frame

- K-Shield Dynamax® Impact Idler Frame

All Kinder Idler Frames feature standard high quality hot-dipped galvanised steel, painted steel and stainless-steel option is also available.

Kinder Australia’s Applications and Engineering team can assist with proactive site analysis and audits. They can check your site’s framework from all angles to ensure that it is level and square, whilst advising whether your conveyor is at risk of misalignment. The team can recommend the ideal idler frame to fit, to providing an optimal and supported conveyor.

For a wide variety of idler frames that will continue to provide ample alignment to your conveyor, talk to the specialists at Kinder Australia to determine the best option for your application.

Adjustable Conveyor Trough Frames (Inline & Offset)

Can be installed at the head and/or tail transition zones of all types of conveyors. These frames replace the need to have an already predetermined mounting/feet hole pitch and/or position, whilst using fixed angle transition frames.

- Multiple adjustable angles range available.

- Available in both inline and offset configuration.

- Available for all belt widths.

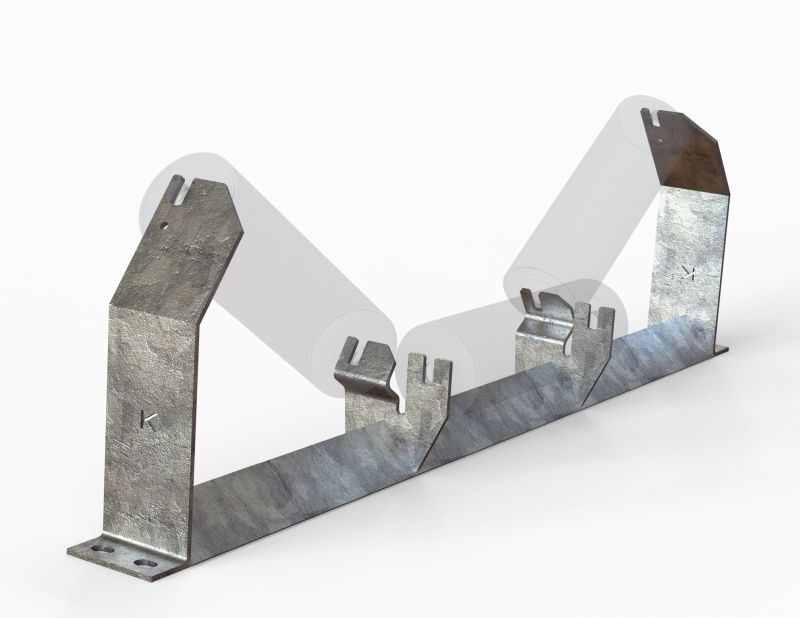

K- Vee Return Idler Frame

These idler frames provide low maintenance and effective belt alignment, accommodating both rubber and polyurethane discs.

These discs are positioned at regular intervals to effectively eliminate roller build up. They can also be bunched together at both ends of the idler frame to provide ample support and protection to the belt edges.

K-Vee Return Idler Frames tolerate a limited amount of belt drift. The ideal application covers wet, sticky or abrasive materials that adhere to the belt surface.

Designed to replicate the offset profile in a stronger inline format that suits most standard systems. The main advantage of this replication means the belt profile is kept uniform; this consistency translates to longer belt wear life as well as improving conveyor belt support at impact load zones.

- Easy maintenance due to the frame’s retractability and accessibility to both sides of the conveyor.

- Best suited for offset configurations and is more heavy duty than standard retractable idler frames.

- Stronger frame system due to centrally located rollers and dual transoms.

- Available in any belt width, any angle and profile.

- Flexibility to scale up for belt width applications greater than 1200mm.

Features an innovative retractable design that facilitates easy and efficient roller change out in all roller locations.

The solution is effective in removing the hassles associated with roller replacement, minimising safety hazards and maintenance downtime.

- Provides ease of accessibility to both sides of conveyor.

- Allows for easy maintenance.

- Suitable for use in tight and restricted locations.

Kinder offers a comprehensive range of K-Commander® Tracking Frames that help to minimise belt mistracking and associated problems of material spillage, reduced life to the conveyor belt and the conveyor structure.

The K-Commander® Tracking Frame range is highly effective for Return, Trough, Flat Return an Inverted Vee Return applications.

K-Ergo Swift Return Idler Frame

Roller change outs are quick and seamless, with access to only one side of the conveyor required.

The ingenious flip down design eliminates the need for belt jacks as the belt does not need to be raised out of the way to lower the frame.

- Fully galvanised frame.

- Allows for single side access and roller changeout.

- Provides safer and quicker manual handling.

- Custom flat return, vee return and trough side designs also available upon request.

K-Shield Dynamax® Impact Idler Frame

Ideally suited for heavy duty applications, particularly within mining environments and for high-capacity conveyors, with no limit on belt speed, belt width, lump size, TPH or drop height.

Consists of a dual trough roll configuration matching the existing trough profile, this feature is designed to offer optimal, uniform cross-section, whilst maximising the overall loading capacity of the system.

K-Shield Dynamax® Impact Idlers are suspended above anti vibration / spring element mounts, providing maximum cushioning and absorption of the conveyed materials impact.

- Heavy duty frame can be custom designed to suit specific applications.

- Additional jack down/lowering access facility.

- Sway bar suspension utilises polyurethane bushes for optimum stability, whilst enabling the idler to move up and down when impacted.