K-Slide®: 84% Lighter, 50% Smaller. Safer to Handle. Faster to Install.

OVERVIEW

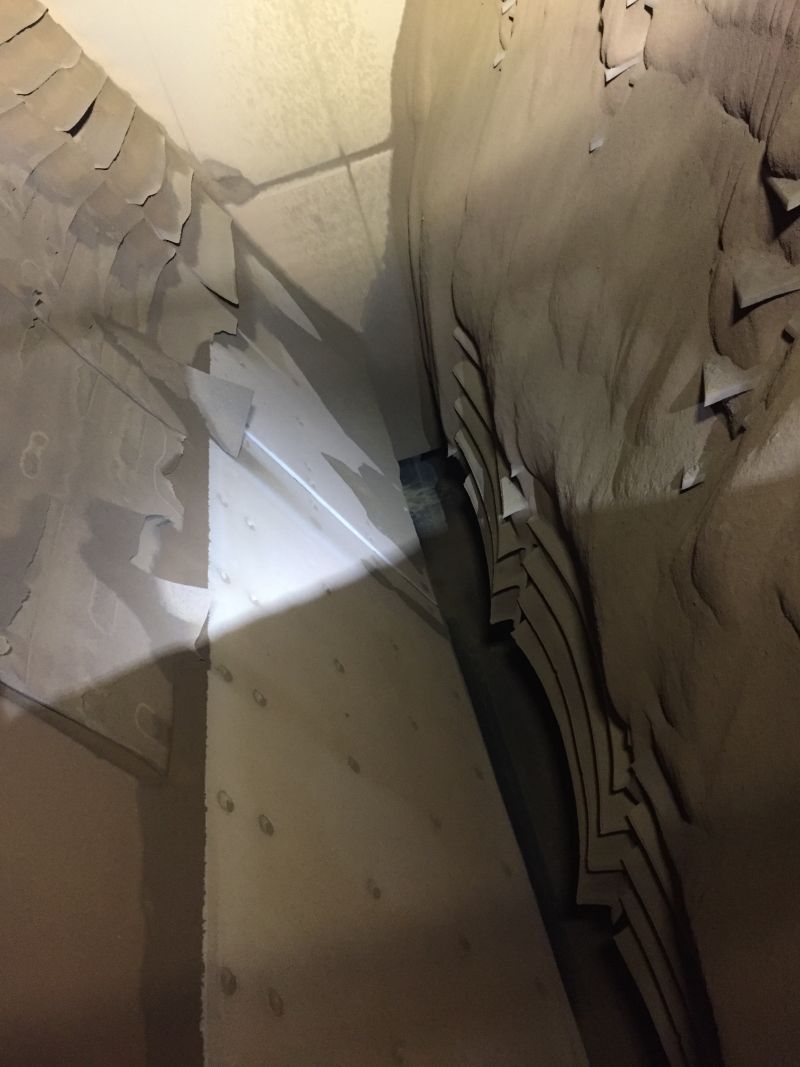

At a major iron ore export terminal in Western Australia, one of the world’s leading mining companies was experiencing persistent material flow problems within their fines chutes. Handling iron ore fines (6 mm minus), the site struggled with product sticking to the chute walls and forming bridges between liners. These blockages disrupted production, increased maintenance demands, and posed unnecessary safety risks for maintenance teams.

To address these issues, the company partnered with Kinder Australia to trial a modern liner solution engineered to improve product flow and reduce manual handling hazards. The new system needed to integrate seamlessly with the current chute configuration while delivering measurable gains in reliability, safety, and overall performance.

CHALLENGE

- Frequent downtime and labour-intensive maintenance caused by material build-up.

- Safety risks due to heavy, difficult-to-handle liner panels.

- Need for a lightweight, low-friction liner compatible with existing mounting points.

The previously installed Duaplate® and rubber-based liners were not suited to the behaviour of fine, sticky iron ore. Material frequently adhered to chute surfaces, forming flow restrictions and resulting in unplanned shutdowns. In addition, the weight and rigidity of the old liners made removal and replacement difficult, increasing manual handling exposure and extending maintenance shutdowns.

Operators required a liner solution that would deliver a durable, low-friction surface, match existing bolt patterns, and significantly reduce panel weight. The overarching goal was to eliminate blockages, stabilise throughput, and simplify maintenance – without increasing operational costs or introducing installation complexity.

SOLUTION

Kinder Australia recommended the K-Slide® UHMWPE Low Friction Liner and Fasteners, designed to minimise wall friction, prevent product hang-up, and maintain uninterrupted material flow. The first phase involved a trial installation in the lower section of the fines chutes, using liners matched precisely to the existing thickness and bolt-hole layout.

Following strong performance in the trial area, the site progressively expanded K-Slide® across additional chute locations and increased liner thickness to extend service life. Four years later, during a subsequent maintenance cycle, Kinder engineers further optimised the system by reducing liner panel size by 50%, resulting in lighter, more manageable components that significantly improved safety during installation and replacement.

Both K-Slide® and K-Floshield® were evaluated, but K-Slide® was ultimately selected for its lightweight construction, ease of handling, and proven anti-bridging capabilities – critical advantages for crews operating in demanding production environments.

RESULTS

- Material bridging and build-up fully eliminated.

- Downtime and maintenance requirements substantially reduced.

- Improved safety through 84% lighter, 50% smaller and easier to install liners.

- Consistent material flow and strong opeator endorsement.

The installation of K-Slide® UHMWPE liners resolved all material hang-up and bridging issues, delivering smooth, uninterrupted flow across every chute where the system was installed.

The site experienced a marked reduction in downtime and reactive maintenance, contributing to higher overall plant productivity.

The redesigned lightweight liner panels also reduced manual handling risks and shortened installation times, delivering a safer working environment for maintenance personnel. Operators reported significant improvements, with feedback including: “extremely happy with K-Slide® as the dirt doesn’t stick to it”.

K-Slide® is now the preferred lining solution at the site, setting a new benchmark for reliable, low-friction performance in iron ore fines handling.