Industry Benchmark | Unmatched Dust-Free & Contactless Conveyor Transfer Point Solution.

The effective containment of dust emissions around high impact load zones and poorly designed conveyor transfer points is of paramount importance to today’s environmentally conscious material handling operators.

For over 35 years, Kinder globally has accumulated a solid foundation, expertise and success in helping operators across many diverse industries address their toughest dust and spillage challenges.

Exclusive to Kinder, we bring you the The Essential AIR Seal – Dust Containment Combination, our latest top end combination conveyor skirting, sealing and belt support system. The Essential AIR Seal is backed by proven engineered technology that promises to deliver industry benchmark, unmatched dust-free, contactless skirting/sealing solution where it’s most needed, at critical conveyor transfer points.

Suited for all bulk materials handling applications, particularly the harshest mining/extractive industries. Dust emissions, material spillage, carry back and associated OHS hazards can be significantly eliminated by installing Kinder’s innovative Essential AIR Seal, creating a highly productive, efficient and safe workplace.

Key Features:

- Engineered conveyor componentry.

- Successfully eliminates dust emissions and material spillage.

- Improves and extends the service of the conveyor belt.

- Reduces OHS Hazards and cleaning up costs due to dust emissions and material spillage.

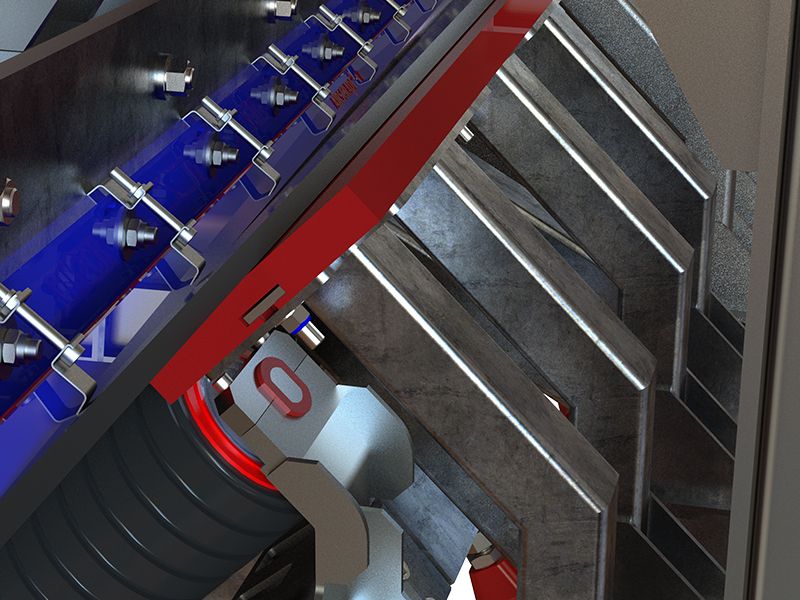

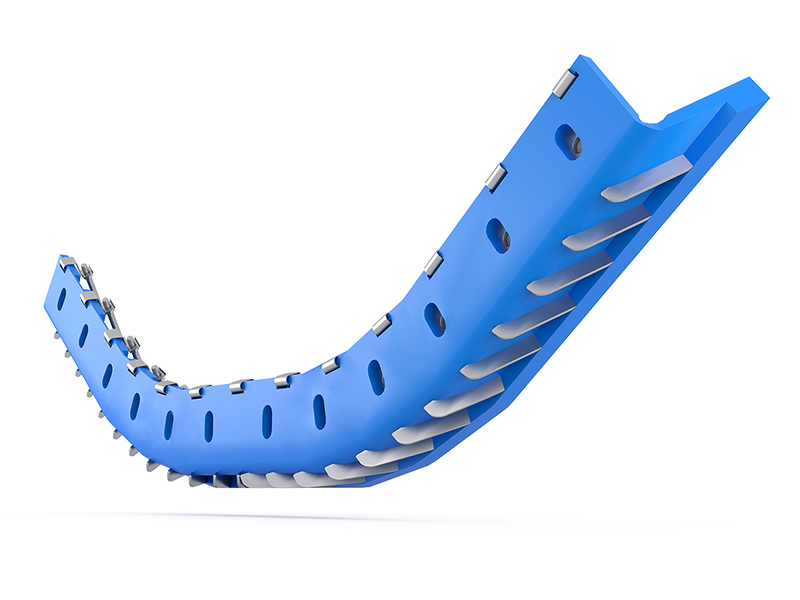

AirScrape® is a highly effective contact-free conveyor skirting and sealing system that acts as a side seal, suspended over the conveyor belt. With its unique diagonal arrangement of hardened lamellae, air is led from the outside into the middle of the belt, creating powerful air suction.

The material movement together with the moving belt support increases the suction effect enabling fine dust particles to remain in the conveyor section.

The AirScrape® innovative and patented design delivers a tri-fold positive effect that includes material spillage and dust formation reduction particularly at critical transfer points. Additionally, due to the skirting and sealing system’s ability to hover freely above the conveyor belt, skirt friction and belt damage can be eliminated, service life of other conveyor components can also be extended.

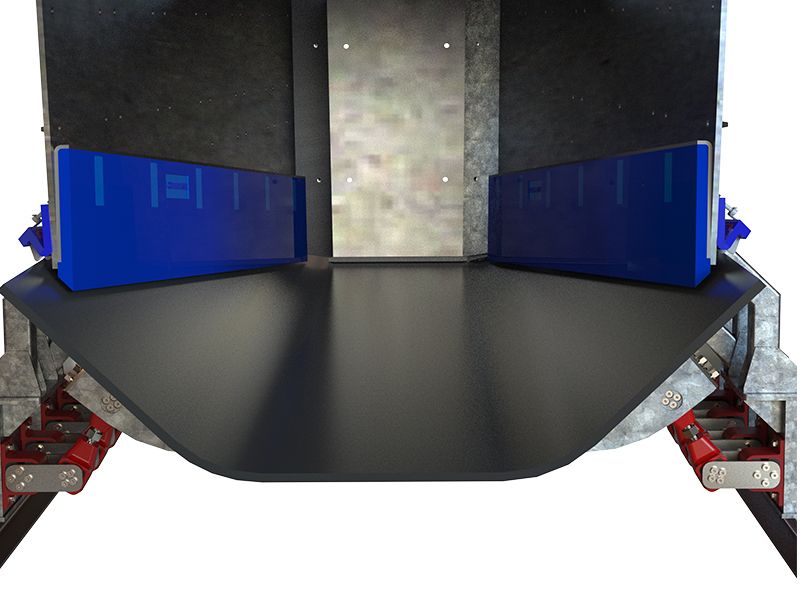

TailScrape fully integrates with AirScrape® to deliver outstanding sealing at the rear area, resulting in next level dust control, material spillage reductions and significant cost savings and resources.

The Tailscrape proprietary and intelligent blade structure on the underside ensures a negative pressure environment within the conveying area. The negative pressure created prevents dust and other material spillage from escaping through the millimetre-thick gap, by up to 100%.

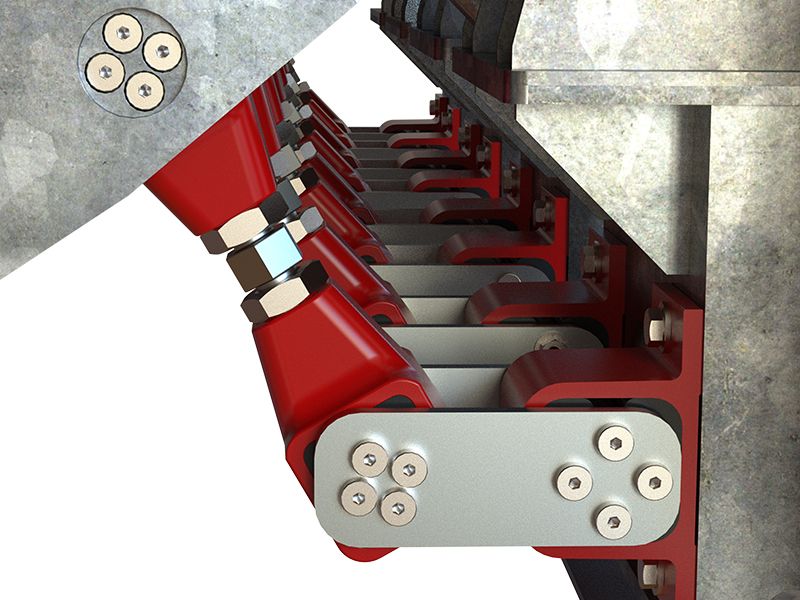

The K-Containment® Seal enhances the success of the outer seal by reducing the high internal pressure experienced inside the chute and protects the vulnerable chute edges from damage.

K-Containment® Seal is also an engineered polyurethane system and offers exceptional resistance to wear. The slotted arrangement allows for installation adjustment to ensure that material and fines cannot be trapped and so reducing the risk of premature belt damage.

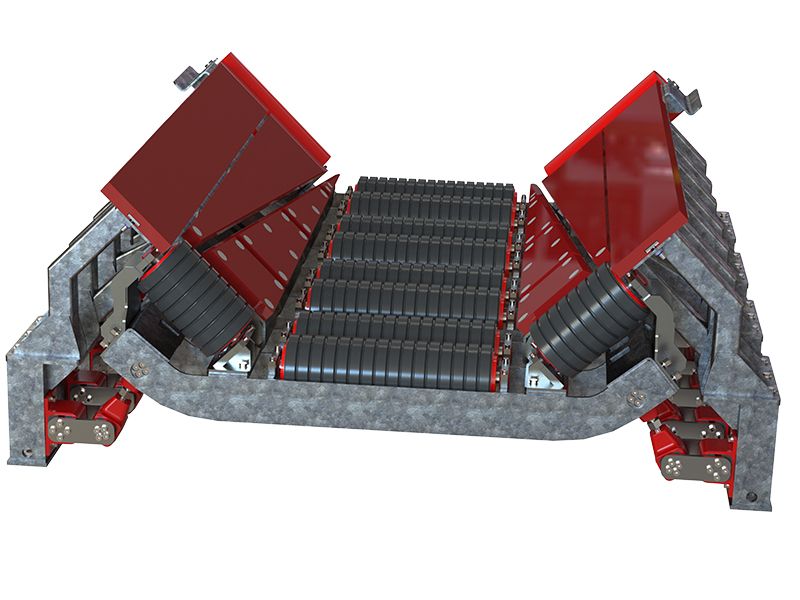

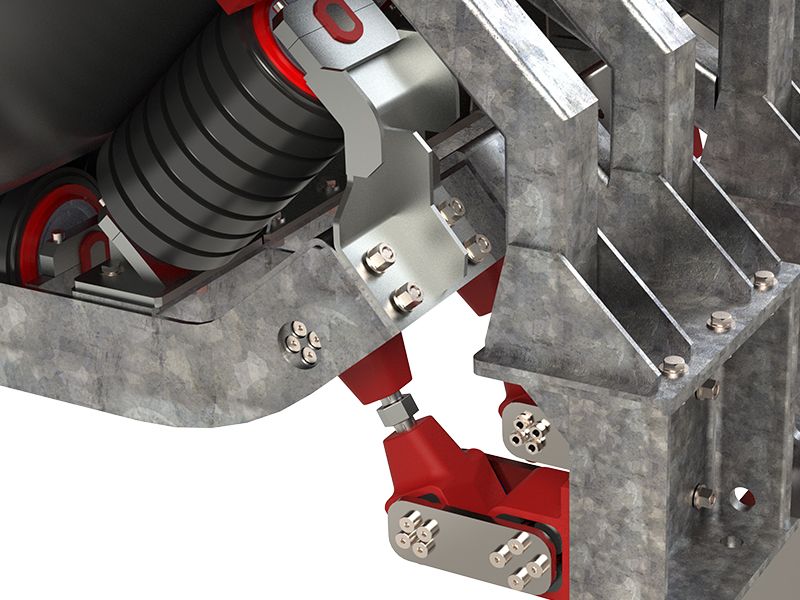

K-Shield Dynamax Combi Impact Bed features an innovative Tapered Skirt Support Zone and “IDS” Independent Dynamic Suspension.

Our in-house engineered designed technology allows each twin centre impact roller to move independently of the other impact rollers and the Static Slider Rails provides optimal belt support at critical transfer points.

The Combi Impact bed also incorporates a roller bush innovation. The Polyurethane Bushes prevent damage to the steel roller support frame and roller shafts themselves, increasing the life of these parts or components.

K-Sure® Belt Support System is designed to provide a consistent and stable support for the troughed belt profile by reducing the number of rotating components. The Support System eliminates any belt edge sag and therefore increases the effectiveness of the skirting seal.