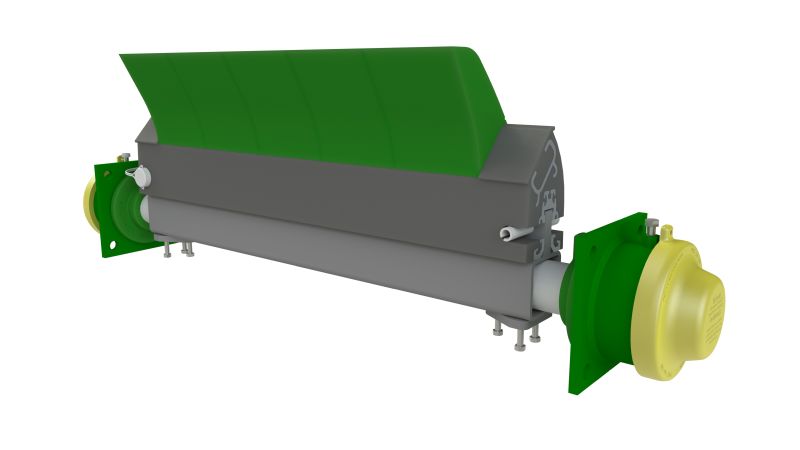

Super Heavy-Duty Applications

The Eraser SHD™ system is a rugged mine duty system, designed for extremely abusive environments with a 286mm polyurethane blade. The Eraser SHD™ system comes with a single piece polyurethane blade carrier that allows easy maintenance and tip segment replacement. This blade allows for only the tip to be replaced when it becomes worn, rather than the entire blade. And as it comes in 152mm lengths, in cases of uneven wear, you can replace just the worn section.

This system uses the Super Eraser™ 6 mm thick, 89mm x 89mm tube stock steel mainframe and corrosion-resistant, galvanised Schedule 160 pipe stub ends for high rigidity and long-lasting durability.

Key Benefits

- Replaceable blade tip means quick blade change out with less downtime.

- For use on conveyors with large head pulleys, high throughputs, harsh conditions and/or fast belt speeds.

- Extremely effective cleaning performance with a 286mm Raptor blade.

- Heavy duty mainframe for reduced blade deflection and consistent blade pressure.

- The Perma-Torque™ internal central tensioner is adjustable from 40 to 183 Nm resulting in uniform cleaning pressure to the conveyor belt.

- Compact mounting footprint only protrudes 140mm from mounting structure.

- Safety yellow coloured end caps seal the Safe Torque™ ratchet from dust and water contamination.