Dust is an inevitable byproduct of material handling and processing, especially in mining, quarrying, and construction industries. While some dust emissions are intentional—producing fine materials for specific uses—uncontrolled dust can wreak havoc. From health hazards to equipment damage, uncontrolled dust can cause significant issues. Here’s a list of practical solutions for suppressing and controlling dust effectively:

1. Install Effective Skirting Systems

Transfer points are often the dustiest parts of a conveyor. Skirting systems create a seal to prevent dust from escaping. Contact skirting offers a snug fit against the belt but requires more maintenance due to wear over time. Conversely, contactless skirting is more durable and cost-effective in the long run, as it doesn’t wear out as quickly.

2. Support Your Belt Profile

A consistent belt surface ensures skirting systems work correctly. Static supports are ideal for low-impact areas, while impact or dynamic beds are better suited for heavy loads. Proper belt support prevents sagging, creating gaps for dust to escape.

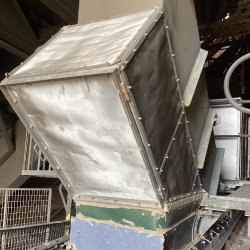

3. Use Belt Covers

Belt covers shield material from wind and vibrations that can disturb settled dust. Rigid covers like the K-AllShelter® Belt Cover provide strong, enclosed protection, while flexible mesh covers offer better airflow and visibility. Both options help trap dust effectively during transport.

4. Control Dust at Discharge Points

Discharge points are another common source of dust. Dust curtains are great for enclosed areas, while extendable loading chutes minimise dust when material is discharged into open spaces like stockpiles.

5. Incorporate Water Sprays or Extraction Fans

Water spray nozzles and fans can suppress airborne dust effectively, but they require careful planning. Water sprays need proper drainage to manage runoff, and fans require regular maintenance to keep filters working efficiently. These are excellent options when handled correctly.

6. Prioritise Belt Cleaning

Carry-back on the underside of the belt creates dust issues in unprotected areas. Installing effective belt cleaners minimises carry-back, reducing dust generation throughout the system and improving overall material recovery.

Dust suppression isn’t just about meeting safety standards—it’s about protecting your team, extending the life of your belt, and maximising productivity. Identifying and addressing dust issues can significantly affect your operation’s efficiency and safety.

Not sure where to start? Book a professional conveyor inspection today by filling in the form below. Kinder’s Field Application experts can pinpoint problem areas, recommend tailored solutions, and help you create a cleaner, safer, and more efficient workplace.

Request Consultation

"*" indicates required fields