Operational efficiencies rely on the correct installation of all of the associated mechanical components. Incorrectly installed equipment will result in production target losses (we have seen cases of frames installed back to front) and can adversely affect belt tracking and material spillage leading to the premature wear or damage of the conveyor belt.

The purpose of this “How To” guide is to clearly explain the correct installation procedures for conveyor idler frames.

OPERATING AND MAINTENANCE INFORMATION

- Achieve efficient operation and maximum life from rollers and equipment, it is important that the operating conditions be as clean as possible.

Any spillage’s which occur should be cleaned up regularly and not allowed to build up on decking plates or walkway or at any other point where it may obstruct operations. - Is important to ensure that any conveyor rollers or pulleys that require repair or replacement should be dealt with as soon as possible to avoid the possibility of belt damage.

- Sure belt heights of trough rollers are level on horizontal runs or are correctly set to respective heights on vertical curves. Rollers with incorrect respective heights may lead to damaged belt or roller and belt.

Images of conveyor damage resulting from incorrect frame maintenance.

Image of a Kinder Australia Offset Trough Frame

FRAME INSTALLATION

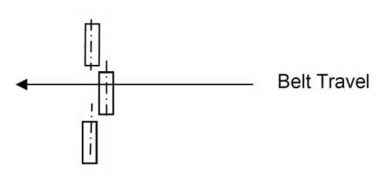

a) Standard Frames

Ensure offset type idlers are installed correctly relative to belt direction. The centre roll “sees the belt first”.

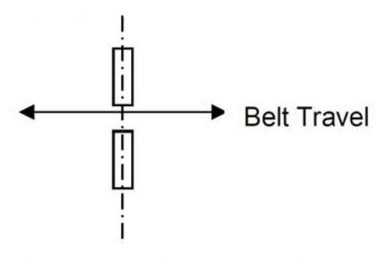

b) Inline Frames

Inline frames can be installed either way.

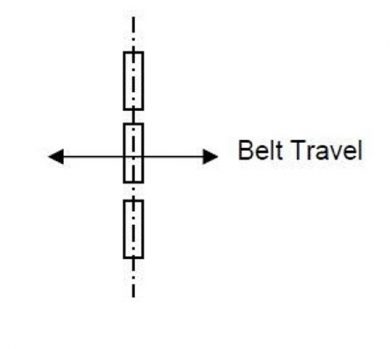

c) Return Frames

Return frames for vee return sets and brackets for flat return sets can be installed either way.

d) Training Frames