Kinder celebrates 40 years of innovation, learn more about the journey from the beginning.

N.C. Kinder & Co. Pty Ltd was founded by Neil and Christine Kinder, driven by their passion for excellence and innovation.

CRM program Tracker was used to develop and retain Kinder’s comprehensive customer database.

Travelling around Australia to meet with customers, this was the beginning of the field applications specialist team at Kinder.

Kinder’s distinctiveness is defined by strategic marketing. The core message resonated: Kinder embraces the hands-on approach, unafraid to get their boots dirty.

Kinder commences shipments from the USA, signalling the start of an international journey towards a global horizon.

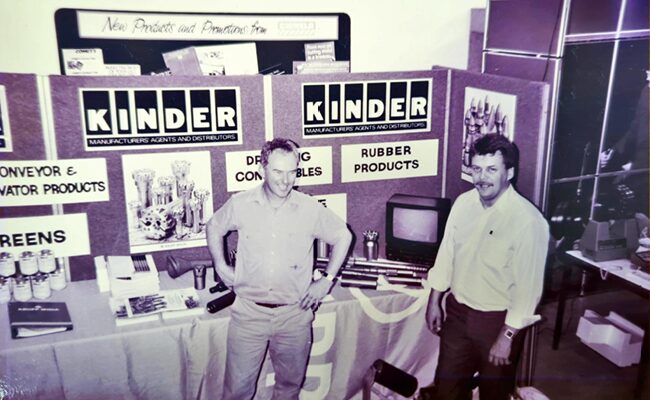

Kinder makes its debut at CIVENEX 1990, paving the way for brand exposure and networking within the engineering and construction industries.

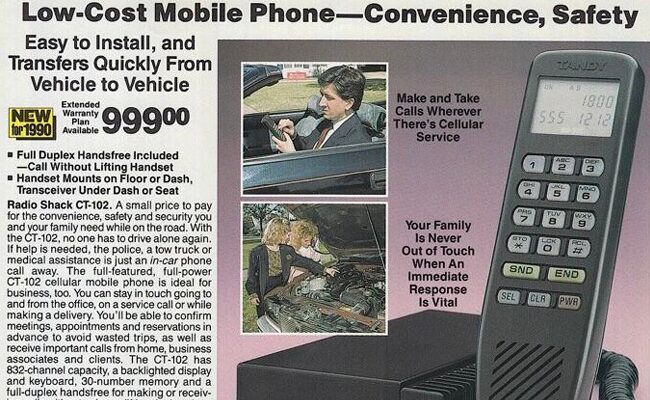

Foresight meets innovation; a mobile car phone is secured allowing Kinder to capitalise on the expanding mobile network. Kinder’s reach extends significantly to a nationwide presence.

Kinder Engineering takes a significant stride forward as Kinder welcomes its first engineer, reinforcing the commitment to expertise and advancement.

Kinder embraces the digital era with the launch of its website www.kinder.com.au connecting with audiences worldwide and ushering in a new chapter of online presence and accessibility.

With traditional rubber skirting proving to overheat with high friction usage, K-Superskirt® was developed to provide 76% less friction and last 8-10 times longer. Australian customers were impressed with this durable new polyurethane solution.

Kinder proudly earns the title of Supplier of the Year at the Bulk Handling Awards 2008. This achievement recognises Kinder’s superior solutions for the bulk material handling industries.

High speed / high capacity belt support applications were possible for the first time internationally with the introduction of this exciting applied technology. K-Glideshield® was installed at Loy Yang Power Station, Latrobe Valley.

Making the transition to a unified platform, the implementation of SAP Business One was a monumental step forward in Kinder’s organisational efficiency.

To ensure a precise fit, K-Sure® Support was improved with the addition of a specialised stud and stronger design. This allowed for adjustment to suit 3 different size roller diameters, offset/inline frames, and manufacturing tolerances in trough frames.

Kinder attains ISO certifications 9001, 45001, and 14001 for unwavering dedication to quality, occupational health and safety, and environmental standards.

Relocating to a brand new 8900m3 facility in Braeside, not only accommodates the storage of over 15,000 stocked items but also provides ample space for the growth of staff and office operations.

The development of K-Shield Dynamax® Impact Idler for a leading iron ore client in Western Australia stands as one of the first major custom engineered projects, firmly setting Kinder apart as industry innovators.

Kinder secures the title of Supplier of the Year at the Bulk Handling Awards 2022 reaffirming their position as a leading global independent supplier and manufacturer of innovative, in-house designed material handling solutions.

A consortium led by Attalis Capital, including the Victorian Business Growth Fund (managed by Roc Partners), completed the successful acquisition of Kinder Australia. This marks an exciting new chapter for the business, building on its strong legacy and positioning the company for long-term growth and innovation.