Dust exposure is a serious occupational hazard in materials handling operations, with crystalline silica dust posing significant risks to workers and the environment. Silicosis, a non-curable occupational disease is just one of the severe health conditions caused by prolonged inhalation of silica dust. This issue is particularly relevant for industries such as mining, sandblasting, quarrying, and cement production, where large amounts of dust are generated.

While seemingly harmless, crystalline silica dust can cause lasting harm if not properly controlled. As companies become more aware of these risks, implementing effective dust containment strategies has become a top priority.

At Kinder, we explore the risks of dust exposure in the industry and workplace. As an organisation, we’re also committed to educating the industry about the dangers of dust exposure and providing solutions to mitigate these risks.

Health Hazards of Dust Exposure

Prolonged exposure to crystalline silica dust can lead to severe and irreversible health conditions:

Silicosis: Lung tissue damage and scarring reduce lung capacity, leading to lifelong impairment.

Lung Cancer and COPD: Increased risk of respiratory diseases due to silica exposure.

Despite the mandatory use of PPE like gas masks, adherence can vary, leaving workers vulnerable. Kinder is at the forefront of raising awareness and offering solutions to minimise these risks.

Environmental Impact of Dust Emissions

Dust emissions don’t just harm workers, they also negatively affect surrounding communities and ecosystems.

Health of Residents and Animals: Crystalline silica dust can harm nearby residents, pets, livestock, and wildlife, potentially causing conditions similar to those found in humans.

Environmental Contamination: Uncontrolled dust can pollute air and soil, exacerbating ecological challenges.

While PPE protects workers, only comprehensive dust control measures can mitigate these broader environmental risks.

Dust Control Strategies for Safer Operations

Containing dust emissions, particularly around high-impact load zones and poorly designed conveyor transfer points, is crucial for environmentally conscious operations. CEOs, company owners, and industry professionals must take decisive action to protect their workforce and the environment by adopting robust dust suppression strategies.

Kinder’s solutions are tailored to address specific applications, ensuring efficient dust containment:

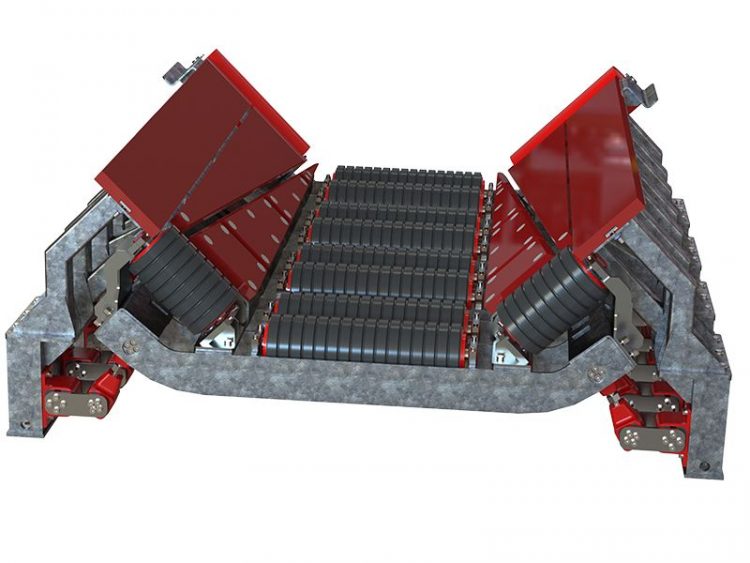

The Essential AIR Seal System is an advanced conveyor solution for eliminating dust emissions, spillage, and OHS hazards across all materials handling operations. The combination conveyor skirting and belt support solution include the AirScrape®, TailScrape, K-Containment® Seal, and K-Sure® Belt Support System, all designed for efficient dust containment, superior sealing, and extended conveyor life.

AirScrape® uses a patented design to create an air suction effect that traps fine dust particles within the conveyor, drastically reducing dust emissions and spillage. Its contact-free operation prevents belt wear, ensuring long-lasting performance.

Engineered for safety and efficiency, the Essential AIR Seal System provides a cleaner, more reliable material handling process.

K-AllShelter® Conveyor Covers protect conveyors from harsh weather and control moisture levels in materials. Providing an additional barrier to airborne dust while protecting personnel and the environment.

Proven Results in Dust Suppression

A Queensland cement production operator recently adopted Kinder’s Essential AIR Seal System, achieving remarkable results. The maintenance team reported a 98% reduction in dust emissions and material spillage, with no belt damage or ongoing maintenance required. “The Essential AIR Seal solution is a huge improvement compared to our initial setup,” noted the site manager.

For over 40 years, Kinder has been a leader in conveyor engineering, helping operators across diverse industries overcome dust challenges. Our innovative conveyor components optimise productivity, efficiency, and safety, ensuring long-term operational success.

Our latest video highlights our engineered dust and spillage solutions, customisable for various applications and environments.

Contact Kinder today for expert guidance on reducing dust emissions, safeguarding your workforce, and fostering a compliant, sustainable workplace.