Uncontrolled dust in the workplace presents significant dangers, including the risk of developing silicosis. To protect workers, the environment and conveyor equipment, implementing an effective dust suppression system is crucial. Dust suppression systems are essential in managing and containing dust around conveyor transfer load zones, reducing clean-up costs and minimising health hazards.

At Kinder, we’ve got your conveyor dust control covered with these engineered conveyor solutions:

In bulk materials handling industries across Australia, dust containment solutions play a vital role in maintaining a safe work environment. Our advanced conveyor dust suppression systems are designed to control and suppress dust effectively, ensuring compliance with safety standards and improving overall operational efficiency.

By investing in a reliable dust suppression system, companies can mitigate the risks associated with airborne particles, protect their workforce from silicosis, and maintain a cleaner, safer workplace.

Protecting People, the Planet & Productivity

Dust control is a critical aspect of maintaining safe and efficient operations in industrial environments. Without proper measures, dust can pose significant risks to personal safety, the environment and equipment functionality.

- Risk to Personal Safety

Inhaling fine airborne dust particles poses serious health risks. Additionally it can cause reduced visibility and access in dusty areas which increases the likelihood of slips, trips and falls.

- Risk to the Environment

Dust can escape site boundaries, contaminating sensitive ecosystems like wetlands and rivers, and sparking regulatory concerns and community tensions. Our effective conveyor dust control solutions can combat this challenge.

- Damage to Conveyor Equipment

Accumulated dust can spread quickly, interfering with conveyor equipment, causing unnecessary shutdowns periods, costly repairs and maintenance.

Strategies for Effective Conveyor Dust Suppression

Effective Conveyor Dust Control

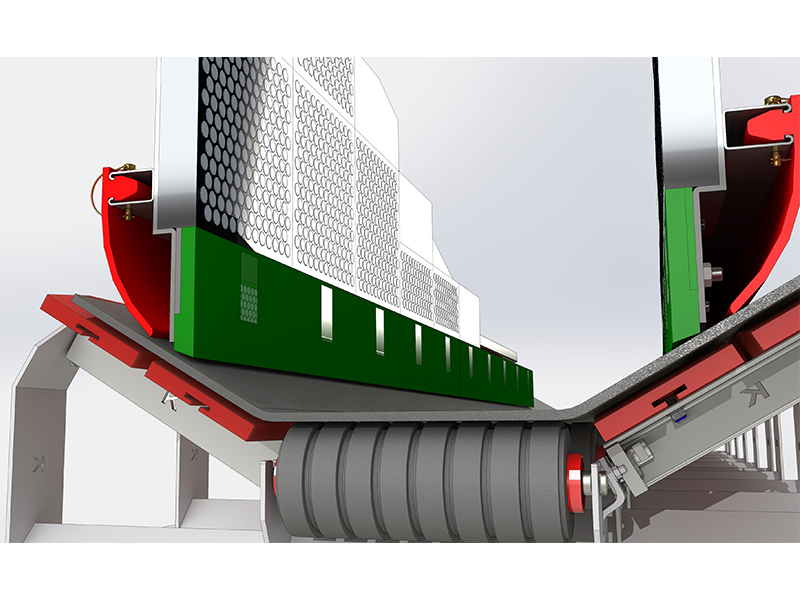

Implementing a comprehensive conveyor dust suppression system is essential to mitigate risks such as silicosis, a serious lung disease caused by inhaling fine dust particles. Effective dust suppression can be achieved by installing skirting and containment seals at conveyor transfer points. Innovative, self-adjusting skirting systems reduce the need for manual intervention, enhancing safety and efficiency.

How to Manage Dust Emissions

To optimise dust suppression, it is crucial to minimise airflow around conveyed materials, especially in overland conveying systems. Using belt covers that provide easy maintenance access helps reduce labour and downtime, ensuring a more efficient dust containment and control process.

To learn more about Kinder’s advanced dust suppression solutions in Australia, get in touch with us today.