Customised Belt Support System Built to Suit Specific Applications.

The elimination of dust emission around high impact load zones and poorly designed conveyor transfer points is key to maintaining clean, safe and interruption free materials handling operations.

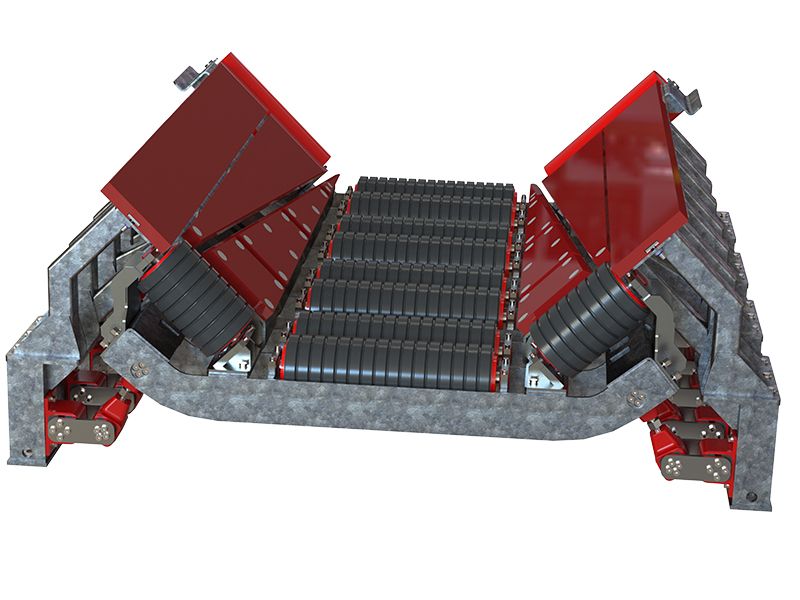

Exclusive and Engineered Design by Kinder, K-Shield Dynamax® Combi Impact Bed delivers world-class conveyor belt support for all bulk materials handling operators, particularly primary crushed ore applications.

Featuring an innovative and robust architecture that delivers increased belt life as impact is absorbed and skirt zone abrasion is significantly reduced. Installing K-Shield Dynamax® Combi Impact Bed at critical transfer points will translate to increased roller/structure life and noise reduction.

Dust emissions and associated OHS hazards can be significantly eliminated by installing K-Shield Dynamax® Combi Impact Beds that help to create highly productive, efficient and safe workplaces.

Key Features:

- Static wing support rails

- Independent Dynamic Suspension

- Polyurethane bushes

- Optional lead in/out wing rollers

- Can suit tapered or parallel chutes (tapered design shown)

Key Advantages:

- Reduced slider bar induced friction design

- Static slider rails maintain skirt gaps.

- Dynamic section for impact absorption.

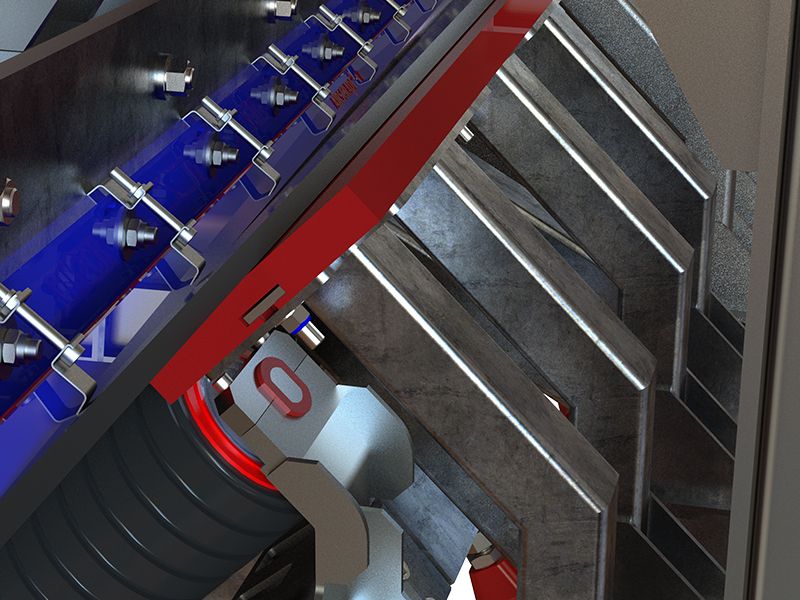

K-Shield Dynamax® Combi Impact Bed features an innovative Tapered Skirt Support Zone and “IDS” Independent Dynamic Suspension.

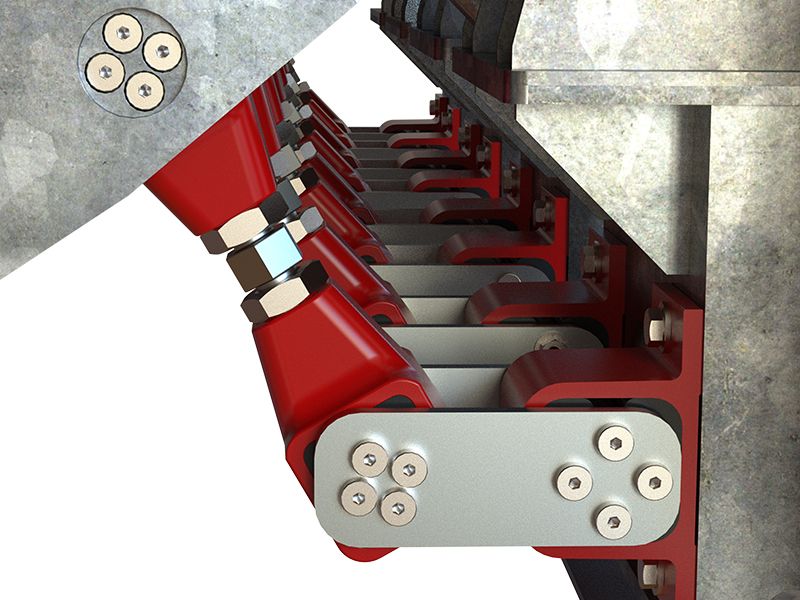

Kinder’s in-house engineered design technology allows each twin centre impact roller to move independently of the other impact rollers and the Static Slider Rails provide optimal belt support at critical transfer points.

The Combi Impact bed also incorporates a roller bush innovation. The Polyurethane Bushes prevent damage to the steel roller support frame and roller shafts themselves, increasing the life of these parts or components.