Kinder Australia is experienced in the design and manufacture of High Capacity / Speed Conveyor Solutions to handle any belt speed and tonnage, within various industries ranging from Mines, Grain Terminals, Port Facilities and Smelters.

High belt speeds lead to greater wear and tear on belt conveyor components, and the risk of vibrations and subsequent component failure or excessive noise. As the belt speed increases so does the loading cycle. The turbulence and impact of the bulk material in the load zone also increases. High-speed operation has a negative impact on belt life because most belt wear occurs in the load zone and the belt passes this point more often than compared to a lower belt speed.

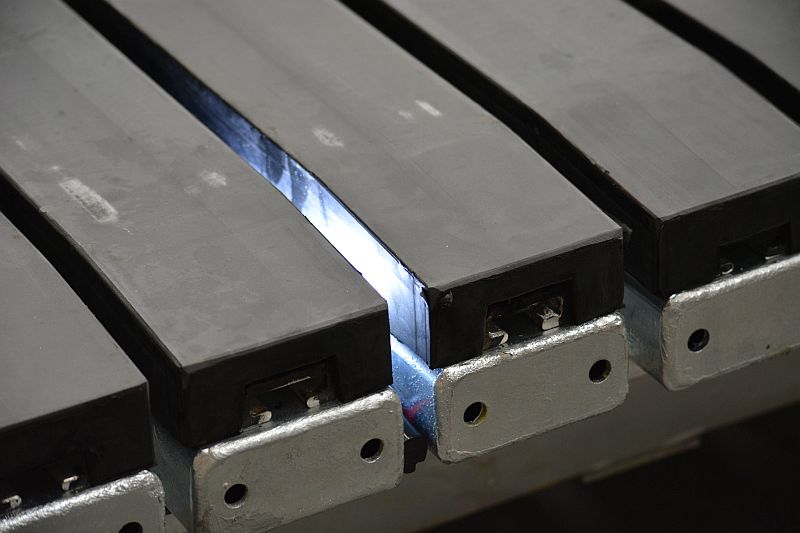

Frictional heat is generated when load zones and transfer points incorporate impact bars and other types of belt support. Conventional impact bars using UHMWPE slider rails are limited by their temperature and heat resistance. So, there is a need to use a higher spec impact or slider bar for higher capacity or speed applications.

K-GlideShield® High Speed / Capacity Impact Bars

Designed specifically for high speed (4m/s or higher) and/or high-capacity conveyors typically 1000 TPH or higher.

Consists of an innovative and proprietary composite material, formulated to achieve the following properties.

- Low coefficient of friction (< 0.1)

- High service temperature, 250° C continuous, 300° C short term.

- Thermal conductivity to dissipate surface heat.

- Certified fire resistant.

- Increased wear resistance.

- Good compressive strength.

- High chemical resistance.

K-Glideshield® Sure Support Rails / K-Glideshield® Combi Suspended Impact Bed

Designed to provide a consistent and stable support for the troughed belt profile by reducing the number of rotating components.

The Support System eliminates any belt edge sag and therefore increases the effectiveness of the skirting seal. Slider rails are available in UHMWPE and K-Glideshield® High Speed / Capacity versions depending on the specific application.

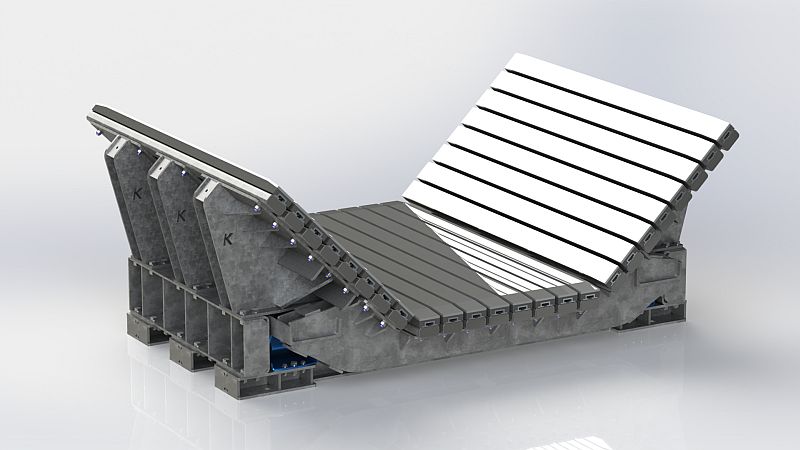

K-Shield Dynamax® Impact Belt Support System

Designed to improve material containment at the conveyor’s transfer point in ultra-heavy duty, very high impact applications

Repeated impact from heavy lumps, long drop heights or lumps with sharp edges can potentially cause damage to the belt top cover.

K-Shield Dynamax® Impact Belt Support features a solid steel structure and manufactured with proprietary K-Glideshield® High Capacity / Speed Impact bars, suitable for the most demanding mining and high-speed applications.

K-Shield Dynamax® Impact Idler

Suited for heavy duty applications, particularly within mining environments and for high capacity conveyors, with no limit on belt speed, belt width, lump size, TPH or drop height. Kinder Australia technical engineers can custom design and manufacture heavy duty frames to suit specific materials handling applications.

Key Features

- Torsion spring element provides maximum cushioning and absorption of the conveyed materials impact.

- Sway bar suspension utilises polyurethane bushes for optimum stability, whilst enabling the idler to move up and down when impacted.

- Heavy duty frame can be custom designed to suit specific application.

- Standard dual 5 roll configuration (10 rollers per idler) also available in any trough angle and roller qty/configuration.