SWITCH CONTROL UNDER EXTREME CONDITIONS

The new robust switchgear series ZS 92 SR / KST has been especially developed for extreme conditions, suitable for application in open-cast mining, gravel plants, quarries and sand pits, recycling plants, waste industry, coal-fired power stations, heavy industrial plant manufacture.

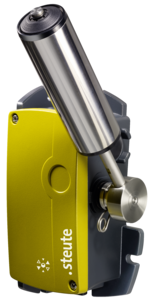

Belt Alignment Switches ZS 92 SR / KST

ZS 92 SR / KST belt alignment switches monitor the alignment of conveyor belts. A large stainless steel roller lever registers when the belt is running off centre between the conveying rolls, for example because it is unevenly loaded, and then – depending on its communication with the control unit – either corrects the alignment or stops the conveyor system.

An outstanding new feature is staggered contacts with individually adjustable switching points. The switching points for advance warning and for switching off can both be individually set within a range of 5-35°. This is made possible through a simple unlocking, shifting and latching of the switching inserts. The switch first generates a warning and at further actuation it stops the belt. These »pre-warning contacts« reduce the downtime of the conveyor: the operator still has a chance to react before the belt stops.

Key Features:

- Temperature resistant from -40 °C … +85 °C.

- High degree of protection IP 66 / IP 67.

- Available in corrosion-resistant aluminium die-cast or thermoset enclosure for application with aggressive bulk goods and environmental conditions.

- Screws and belt alignment roller made of stainless steel.

- Available with toothed shaft P or clamping.

- Belt alignment lever adjustable in 12° steps using a self-locking mechanism

- Back and base mounting possible.